Autorobot in a nutshell

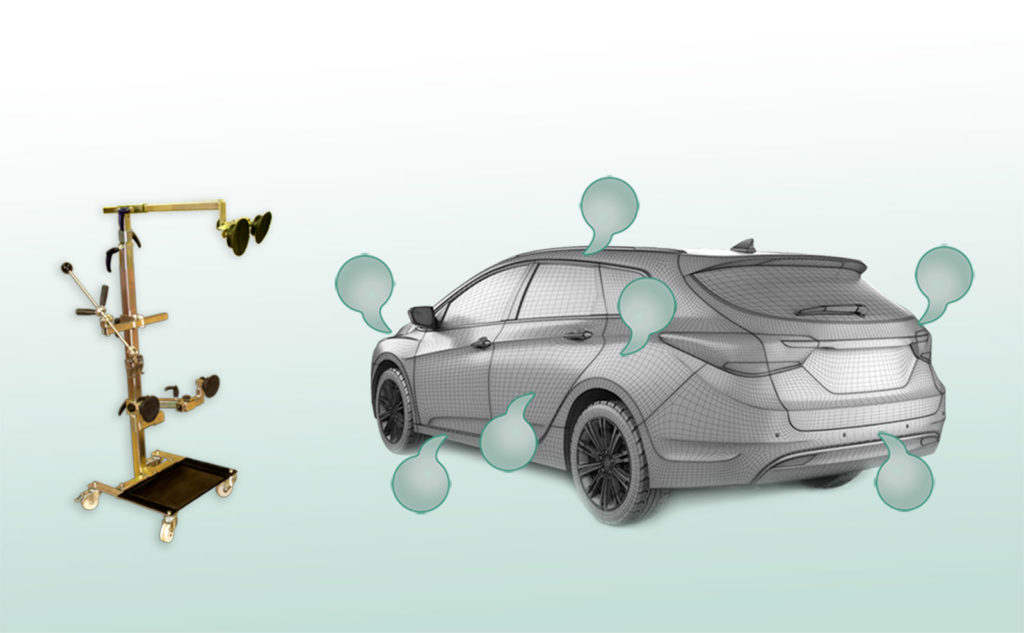

Autorobot Finland Oy designs, manufactures and markets auto collision repair equipment and measuring systems for repairing collision-damaged vehicles. Over 44 years of innovation, our company has brought several new methods – protected with more than 100 patents – to the collision repair industry.

The current product range includes collision repair systems of various sizes which are suitable for both small and large body shops. Speed of straightening work and high product quality are characteristics to all our models. Autorobot products are used on every continent, in over 70 countries. Approximately 80 % of current production is exported.

Starting up and business idea

Autorobot Finland Oy was found in 1969, at the beginning purely as a car body shop as it stayed till 1973. In addition to traditional repair work, company also focused on repairing collision-damaged cars. Repairing collision-damaged cars was expensive, laborious and time-consuming back then, tells Olavi Venäläinen, founder and CEO of Autorobot

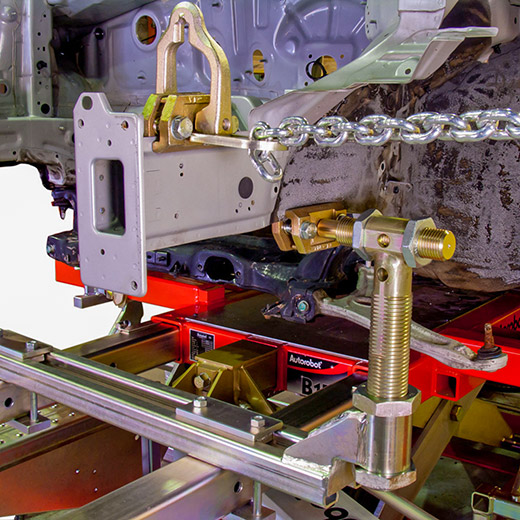

At that time, car body straightening benches were floor models, i.e. one had to crawl under the car to do his job. Therefore almost every body shop worker used to have back problems because of poor working positions. I began to wonder if this could be eased in any way, describes Venäläinen, who himself started working in auto body shops at the age of 15.

My own concrete experience have been the basis of Autorobot’s development work. The base line has been to ease the work and increase the efficiency in body shops and it is proven that Autorobot equipment make work more profitable and efficient. Quality of the work ensures that a properly repaired and safe vehicle returns to traffic.

From domestic market leader to conquer the world

Idea, which was born in Venäläinen’s own body shop, refined into a patented invention through a prototype, where Invention Foundation as well as the top professionals in the field saw ingredients of great success. Invention Foundation undertook to further development of collision repair system and provided financial support when applying for international patents.

We especially wanted to improve working conditions and work ergonomics in body shops. With help of our invention, car body could be raised hydraulically to almost a standing height, which was completely new in this field. Auto body shops soon realized how quick and easy assembling was with Autorobot device compared to previous ways.

The first sales of Autorobot were made in 1977 with Helsinki-based Autokeskus. Autokeskus imported many car brands and ran Finland’s largest collision repair body shop. Cooperation with such a significant party brought credibility to young Autorobot. Word about his new invention was concretely spread by Venäläinen by taking the device on site to body shops.

-There was no other way than personally go on site and show how the device works in practice and that way convince potential customers.

Both Autorobot and Venäläinen were immediately put to a tough test. In Oulu, VW Beetle was brought to the scene as a model car, which, due to its shape, was well-known to be extremely difficult to fasten onto the straightening bench. -The first demonstration, a hundred-person audience and a car which had never been fastened onto the Autorobot bench. It can be said that there was bit of pressure at that moment. Fortunately, it worked out, Venäläinen recalls the time when he was new in the business.

Persistent marketing around the country was fruitful and by 1980s Autorobot was already the market leader in Finland. Since then, Autorobot has been Finland’s only domestic manufacturer of collision-repair systems.

After succeeding in Finland, Venäläinen got the courage to turn his gaze abroad. First test was at Frankfurt Automechanika trade fair in 1978, and at the turn of the decade, export to Europe was already in full swing. After a thorough investigation, Autorobot became a global company when export to Australia started in 1983. During 1980s market expanded all the way to America and Japan.

Since old methods were still in use in many countries, demand for our product was real, as Autorobot was a technology pioneer in the field. Device itself was constantly improved. By 1990s Autorobot brand name was registered in all major export countries around the world.

Winning the obstacles

1980s was an international success for Autorobot, as sales increased by more than 100 % for several years and new production facilities were built in Neulamäki, Kuopio. The future looked bright, but then recession hit the world.

In 1991 products were exported to more than 70 countries and almost all of our turnover came from exports. However, entire automotive industry collapsed due to the international recession and our turnover of FIM 8 million also dropped to just over one million. Situation was challenging, but not impossible.

Since the company have had several financially good years behind it and also some loans had already been paid, the financiers continued to trust Autorobot and wanted Autorobot to stay in business. Autorobot made it by focusing on new markets in Asia, investing in product development and – as always – continuing to work hard.

Recession brought caution to business: growth can no longer be forced, but instead one must adapt to the changes in the market and branch. Restructuring of the automotive industry in the 21st century has eliminated entrepreneurs who were unable to modernize themselves.

Structural change of the 21st century and view to the future

Developing car body straightening work with new equipment solutions has been and continues to be a passion that drives Autorobot forward. It means living and transforming with the industry and being particularly sensitive to messages coming from customers.

Collision damages are no longer repaired in the same scale as before, and more and more cars are being redeemed. Now focus is on repairing small and medium-sized damage. Auto body straightening equipment and measuring data are still needed, but demand is more specific.

Long experience brings continuity to operations of family-owned Autorobot’s company; new generation has grown up and is ready to take over the business. They have learned from Olavi Venäläinen that refining ideas requires maturation as well as ability to tolerate failures.

First you have to have a strong belief in your own work and only then can you inspire others. You have to give your all to this work, meaning that you are responsible to the others as well as yourself. No one can handle it alone, but strength comes from your folks, says Venäläinen with a pride in his voice.

We started Autorobot from scratch, and by studying together and working hard, we have succeeded all the way here.

Our customers tell

Autorobot’s strengths

Ergonomic work enables faster and more efficient working methods that do not strain the technician.

Autorobot Finland’s decades-long trend of innovative work has been positively recognized and awarded with many national and international prizes.

Speed and high product quality of car body repair are characteristics to all our equipment. Efficient car body and chassis work shortens the turnaround time of repair jobs.

With new generation remote-controlled equipment the functions can be controlled near the work station.